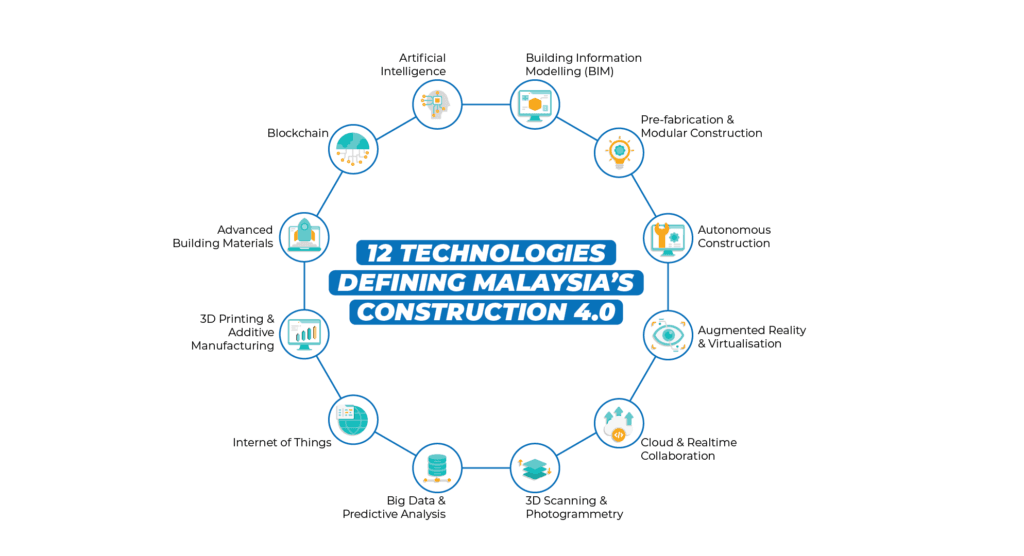

The construction industry in Malaysia is evolving with the adoption of advanced technologies like Building Information Modeling (BIM) and 3D printing. These innovations are not only improving project outcomes but also reshaping the industry’s landscape. Let’s explore how Construction Technology in Malaysia is speeding up projects, improving accuracy, and driving efficiency in Malaysian construction.

The Role of BIM in Construction Projects

Building Information Modeling (BIM) has become a cornerstone of construction technology in Malaysia. It serves as a digital representation of a building’s characteristics, allowing architects, engineers, and contractors to collaborate more efficiently. In projects like the Mass Rapid Transit (MRT) in Kuala Lumpur, BIM played a crucial role. By enabling better coordination of complex underground construction, BIM helped reduce clashes between systems, which often lead to costly project delays. The technology also facilitated real-time sharing of information among stakeholders, improving collaboration and decision-making.

Moreover, BIM’s ability to manage a project’s full lifecycle—from design to demolition—makes it a vital tool for sustainability. By optimizing materials and resources, BIM minimizes waste, helping Malaysia’s construction sector align with global green building trends. With ongoing efforts by the Construction Industry Development Board (CIDB) to promote BIM adoption, Malaysia is on track to meet the goals of Construction 4.0. This is the national strategy for digital transformation in construction.

3D Printing in Construction Technology in Malaysia: Speeding Up Construction

3D printing, also known as additive manufacturing, is another key Construction Technology in Malaysia reshaping the construction sector. By using 3D printers to produce building components, the time required for construction is significantly reduced. For example, walls or building sections can be printed and assembled on-site, cutting down traditional construction timelines.

This technology is particularly beneficial for prefabrication and modular construction, which are gaining traction in Malaysia. The components are manufactured in a factory and then transported to the site for assembly. This process is not only faster but also improves accuracy, as parts are produced with precise specifications.

Digitalization and the Challenges Ahead

Despite the advantages of Construction Technology in Malaysia like BIM and 3D printing, the construction industry has been slow to fully embrace digitalization. One reason is the industry’s reliance on manual labor and traditional methods, which hampers productivity. The COVID-19 pandemic highlighted these inefficiencies, as the sector saw a 19.4% drop in its GDP in 2020. Compared to other industries, construction lags behind in adopting technology, which limits its potential for growth and modernization.

The sector’s dependence on low-wage foreign labor also contributes to lower productivity. Embracing new Construction Technology in Malaysia like autonomous construction, big data, and artificial intelligence (AI) is crucial for improving output. However, small and medium enterprises (SMEs), which make up 90% of the industry, often face financial barriers to adopting these technologies. The lack of organizational planning and standard cost estimation for implementing digital tools further complicates the process.

Success Stories in Digital Transformation

Despite these challenges, some projects in Malaysia have successfully implemented digital Construction Technology in Malaysia. The use of drones, for instance, has transformed site surveys and inspections in high-rise buildings. Drones offer real-time monitoring of construction sites, improve accuracy, and increase safety by reducing the need for workers to access dangerous areas. In addition, drones facilitate data collection for progress management, ensuring that projects stay on track.

As Malaysia continues to navigate the digital transformation of its construction industry, the adoption of technologies like BIM and 3D printing will be crucial for increasing efficiency and competitiveness. Although there are challenges, the successful case studies show that when implemented correctly, these Construction Technology in Malaysia can bring about remarkable improvements in speed, accuracy, and collaboration in construction projects.